SyncMaster – is a computer controlled, hydraulic lifting system that provides THE HIGHEST DEGREE OF safety to personnel and property associated with large-scale engineering / maintenance projects.

Parameters within the lifting system can be set to ensure that the lift does not proceed outside a predetermined lift plan. SyncMaster can in real time monitor and calculate cylinder loads, stroke lengths, total loads and the centre of gravity – all of which will provide the operator with an alarm and automatically stop the lift from continuing should they exceed set parameters. The centre of gravity feature is a function that defines a programmable rectangular or circular boundary outside of which the centre of a mass cannot move. If the centre of mass approaches this boundary, an alarm is given and the lift stops automatically. This is a key safety design feature for use in the movement of tall or unevenly loaded structures. SyncMaster allows for precision control and monitoring of complex lifting applications. Every configuration, process, alert and operator function is displayed and recorded in real time, thus reducing the costly overheads associated with manual control, measurements and comparisons to lift plans. All lift and alert data is collected during the lift process and this data can easily be exported to an application for analysis and planning of future lifts.

THE SYNCMASTER MULTIPLE POINTS SYNCHRONOUS LIFT SYSTEM ALLOWS FOR UP TO 16 POWER PACKS TO BE CONTROLLED BY ONE MASTER UNIT, GIVING A MAXIMUM OF 128 INDIVIDUALLY CONTROLLED CYLINDER POINTS.

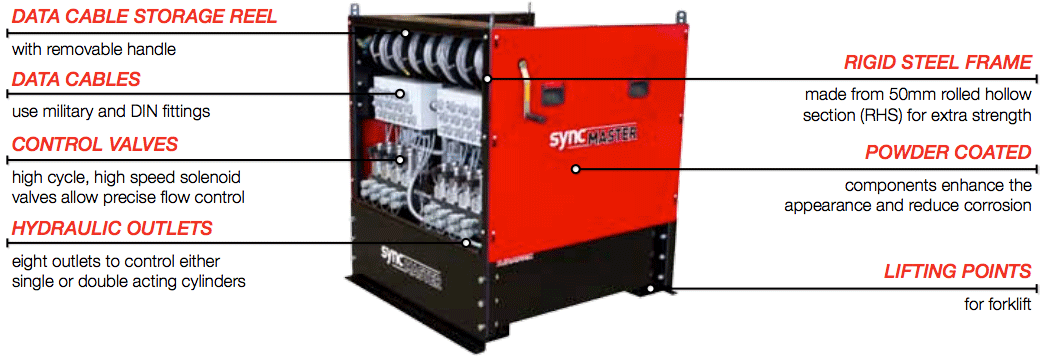

The system constantly monitors cylinder positional and pressure data to safely and effortlessly achieve very accurate and repeatable load movements, regardless of weight distribution or size. One power pack controls up to eight single or double acting cylinders, or groups of cylinders. The ‘X’, ‘Y’ and ‘Z’ coordinates can be recorded for each cylinder, as required by the lift type. DURAPAC cylinder data may be selected from a drop down menu or manually entered for other cylinders. Pressure transducers allow pressure or load limits to be set for an individual cylinder or for all cylinders. Two linear transducers are available per lifting point to monitor cylinder and load displacement. Full data logging and real time graphical display is available for all lift variables.